How It Works

Scatter

is the effect particles have on a light shining through liquid. Typical

engineering units are PPM (parts per million), NTU, EBC, JTU and others. Scatter

is the effect particles have on a light shining through liquid. Typical

engineering units are PPM (parts per million), NTU, EBC, JTU and others.

In a scatter analyzer, light is collimated in a liquid, and the light

scattered (by reflection, etc.) is proportional to the concentration of

particles.

The HSB measures light scatter at a right angle to the incident light.

This has become an international standard, accepted by the EPA in the

United States, the EBC in Europe and other authorities

The Model HSB consists of a flow cell unit and the control/indicator

unit.

The unique 4-chamber design isolates scatter, transmitted and trapped

stray light.

The flow cell includes:

1. The optical light source.

2. The measuring detector which measures light scattered 90 degrees

from the main light path – the nephelometric measurement.

3. The reference detector measures transmitted light from the main

light source to provide a compensating ratio for variations in color,

lamp deterioration and/or fouling of optical surfaces.

4. A test lamp is used to test the measuring detector sensor. This

also provides a light trap.

The indicator/control cabinet contains the modular electronic circuitry

necessary to process signals from the photo-sensors to provide readings in

the required units, to display those readings, to input desired set

points, to indicate alarm levels, to operate relays and to provide

self-diagnostics.

From Light Beer to Coal Slurry…

McNab Clarity Analyzers measure suspended solids in process liquids

with:

- 0.1% Repeatability per year

- Complete international conformance—EPA, DIN, ISO; correlates with

original hazemeter and other instruments

No Standardization Required

The HSB achieves measurement stability of 0.1% per year, allowing

maintenance-free operation. This is made possible by two critical matched

signal verifying modules (SVMs), each with 100-megohm input impedance.

These SVM’s eliminate drift, so there is no need for constant

restandardization. SVM's also correct for any variation in sensor cable

length, so nearby electric interference does not affect operation, even at

cable distances of 600 feet (180m).

Built-in Zero Standard

The unique built-in zero standard can be used at any time to verify

standardization, even when the process is operating. Simply press the test

button, and the system verifies that actual standardization has been

maintained; no drift has occurred. No down time or removal is needed.

High-Sensitivity Measurement In Problem Liquids

New

high technology optics and UV-enhanced sensors deliver 1,000 times more

sensitivity than was possible just a few years ago. The HSB uses this

dramatic improvement to measure suspended solids in "problem"

liquids like dark stout and orange juice. New

high technology optics and UV-enhanced sensors deliver 1,000 times more

sensitivity than was possible just a few years ago. The HSB uses this

dramatic improvement to measure suspended solids in "problem"

liquids like dark stout and orange juice.

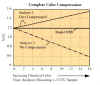

Complete Color Compensation

Color

is "dissolved" in a liquid. Color does not scatter light, but it

will attenuate light, interfering with accurate particle measurement. Color

is "dissolved" in a liquid. Color does not scatter light, but it

will attenuate light, interfering with accurate particle measurement.

To prevent color interference, the Model HSB measures light attenuated

by color and completely adjusts for this interference. The result is

accurate, stable measurements without moving parts or adjustments.

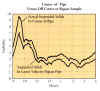

Center-Of-Pipe Measurement

The

ideal scatter measurement is made in the center of the actual process

pipe. Near the pipe wall, in a by-pass pipe or in a slipstream, scatter

particles will settle out because minimum velocity is not maintained. To

eliminate this problem, the HSB measures only in the high velocity region

in the center of the pipe. This is essential for high accuracy measurement

and can yield a 2:1 improvement in accuracy. The

ideal scatter measurement is made in the center of the actual process

pipe. Near the pipe wall, in a by-pass pipe or in a slipstream, scatter

particles will settle out because minimum velocity is not maintained. To

eliminate this problem, the HSB measures only in the high velocity region

in the center of the pipe. This is essential for high accuracy measurement

and can yield a 2:1 improvement in accuracy.

Extended-Life Light Source

Optical

lamp life has been extended to an average of five years by use of optional

improved lamp control circuitry. This makes a truly maintenance-free

system. Optical

lamp life has been extended to an average of five years by use of optional

improved lamp control circuitry. This makes a truly maintenance-free

system.

High Sensitivity For Ultra-Clean Liquids

Measurement of liquids, like WFI and ultra-pure water, requires high

sensitivity measuring geometry. The HSB uses a new, proprietary light trap

chamber to give a 3:1 improvement in sensitivity over the previous state

of the art. This chamber configuration traps stray light that would

otherwise block high-sensitivity measurement, as in other designs.

Model HSB

|

| Principle of Operation: |

Scatter, 90º ratio, nephelometric meets

APHA, ASBC, EBC, EPA, ISO 7027. Color corrected - does not over

respond to color, matches typical laboratory angle of measurement. |

Indicator

|

| Range: |

0 - 2, 20, 200 (199.9) NTU (U)

0 - 2, 20, 200, (JTU/PPM (P)

0, 200, 2000 (199.9) ASBC (A)

0 - 190% Concentration (C) |

| Repeatability: |

0.1% Fullscale per year |

| Sensitivity: |

0.001 NTU (0-2 range) |

| Ambient Conditions: |

32 - 120ºF (0 - 50ºC),

0 - 100% relative humidity |

| Recorder Output: |

0 - 1 mA |

| 4-20 Output: |

Two-wire, ground isolated for computer

application. |

| Alarms: |

Two independent adjustable set-point

alarms 3P/DT 5A resistive unpowered. |

| Built-in test and

fault-isolation: |

Alarms, relays and 4-20 trip when bulb

fails, wetted windows become obscured , or power loss. |

| Housings: |

NEMA 4X (stainless - cabinet) hinged door

W13" x H 16" x D 7" (33 x 41 x 18 cm) for wall

mounting, or semi-flush. |

| Meter: |

3½-Digit LED |

| Weight: |

25 lb./11.3 kg |

| System Test: |

Zero and span, push-to-test switches. |

| Front Panel Instructions: |

Available in English, German, Dutch,

French, and other languages (per customer). |

Flow Cell Assembly

|

| Range: |

Follows indicator. |

| Material: |

Stainless Steel, ASTM 316L/DIN 4435,

other materials available. |

| Windows (optical cell): |

Tempered borosilicate glass, vitreous

silica, TFE 3/8" to 1" (10 - 25 mm) thick. |

| Seals (optical cell): |

TFE, Ethylene propylene, Buna N, PFE,

fluoroelastomer butyl, etc. |

| Flow Chamber: |

Unrestricted, full diameter flow. |

| Operating Pressure: |

150 psig, 10 bar, PN 10 (Contact

factory for higher ratings.) |

| Operating Temperature: |

15 to 225ºF (-10

- 115ºC). Up to 480ºF (250ºC) with air purge. |

| Process Flange: |

Butt weld - typical, (Flange, ASTM, DIN

and threaded and dairy available.) |

| Enclosures: |

NEMA 4 (watertight - blue heads)

NEMA 6 IP68 (submersible - wetted optical cells) IP68

NEMA 7 (explosion-proof heads) |

| Separation from indicator: |

600 ft. (180 meters). Complete with

cables. |

| System Calibration: |

2-point: polymer bead, formazin, or

diatomaceous earth. |

| Specification may be changed or

improved as necessary. |

A90-85B Rev B

|